I made a couple of tests to find good settings to mill acrylic.

I generated the GCODE using Rhino and Grasshopper and I used a 6 mm carbide one flute mill. As a starting point I used the Grasshopper plastic settings: DOC: 4 mm, Feed: 22 mm/s, Plunge: 15 mm/s.

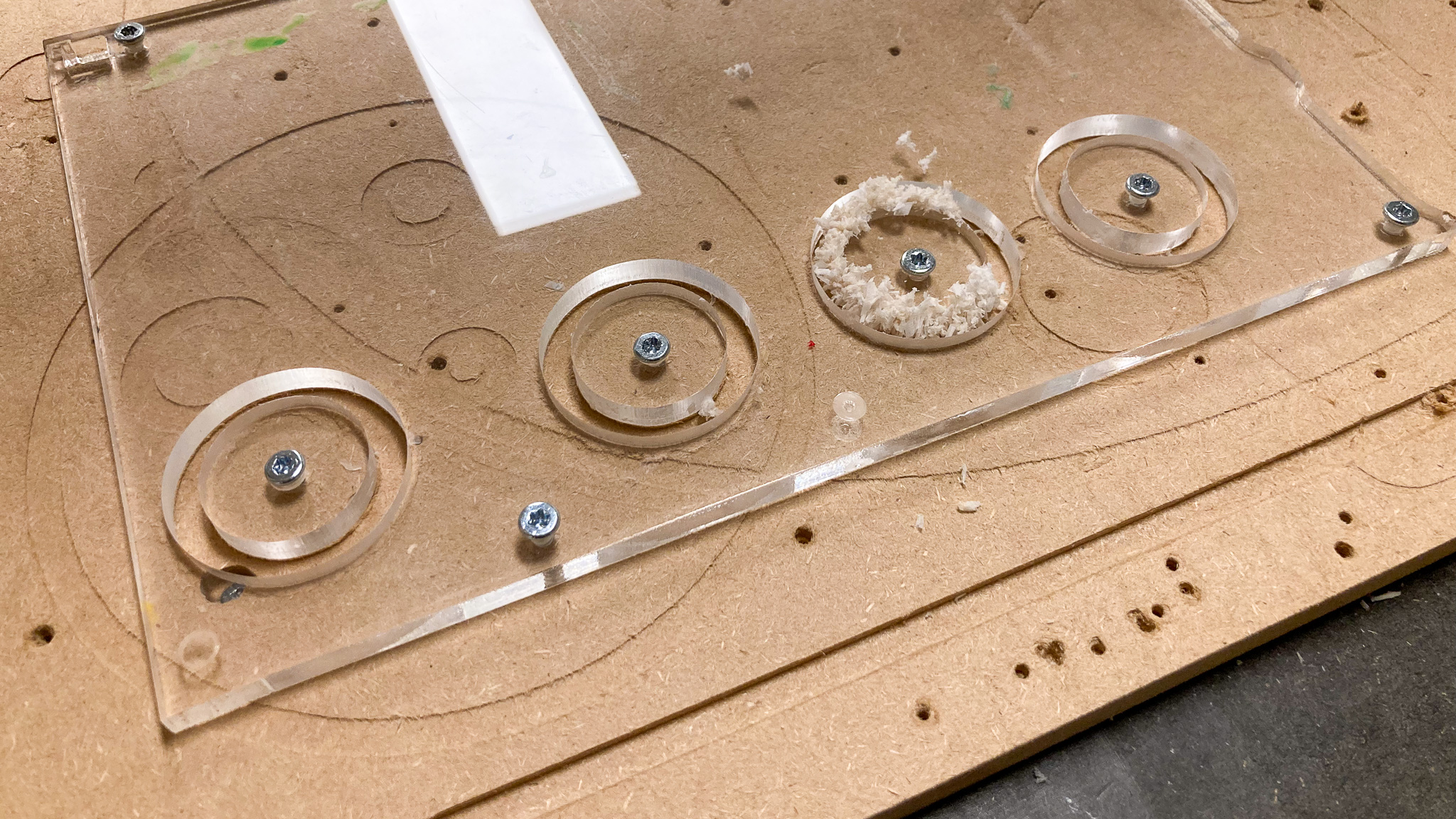

I did cut out multiple 40 mm circles in clear 5.7 mm acrylic with the following variations:

- Enable finishing pass, clear chips with compressed air during milling

- No finishing pass, clear chips with compressed air during milling

- No finishing pass, no chip clearing

DOC: 2 mm, Feed: 30 mm/s, clear chips with compressed air during milling

Clearing the chips with compressed air had a positive impact. In the test without air the chips did melt to the inside part.

Enabling the finishing pass (1.) and going a bit faster with a smaller DOC (4.) had both a slight positive impact. In the future it would be interesting to test doing both.

For 2D shapes in 5.7 mm acrylic I would still use the laser cutter but for thicker acrylic and 2.5D/3D shapes milling is an interesting option.