Rhino / Grasshopper setup

- Download template files from here

- Open

Bark beetle - CNC milling - template.3dmin Rhino

Prepare design in Rhino

- Create rectangle with size of material to use (click rectangle command and type: start point)

- Import design in Rhino

- Fix/adjust design if neccessary (e.g. close shape)

Create rectangle

- Click rectangle command

- Enter (type) starting point (e.g.

0,0) - Enter

width, enterheight

Close shape

- Select lines to join

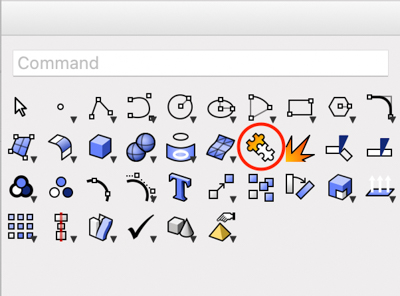

- Click

joincommand (Puzzle icon)

Make tabs

- Create a box (blue cube command) where you want the tab (e.g.

20 mmwide and2 mmhigh) - Move box downwards until the box bottom and workpiece bottom coincide

- Copy box to other places where there should be tabs (press

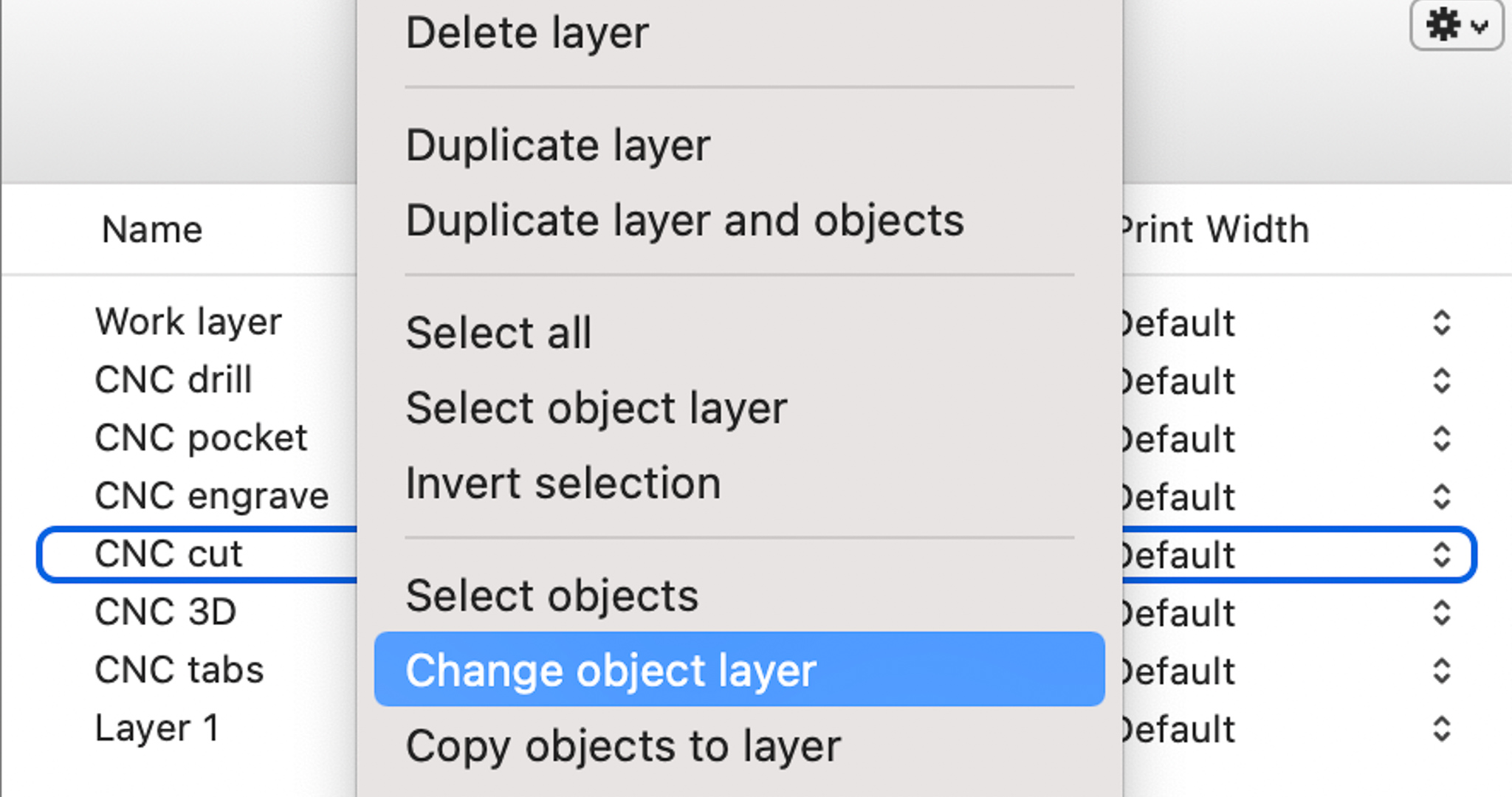

option& move) - Select all boxes, right click

CNC tabs>Change object layer

Create the cutting toolpath next. In the cutting toolpath preview it should be visible that the tabs are not cut

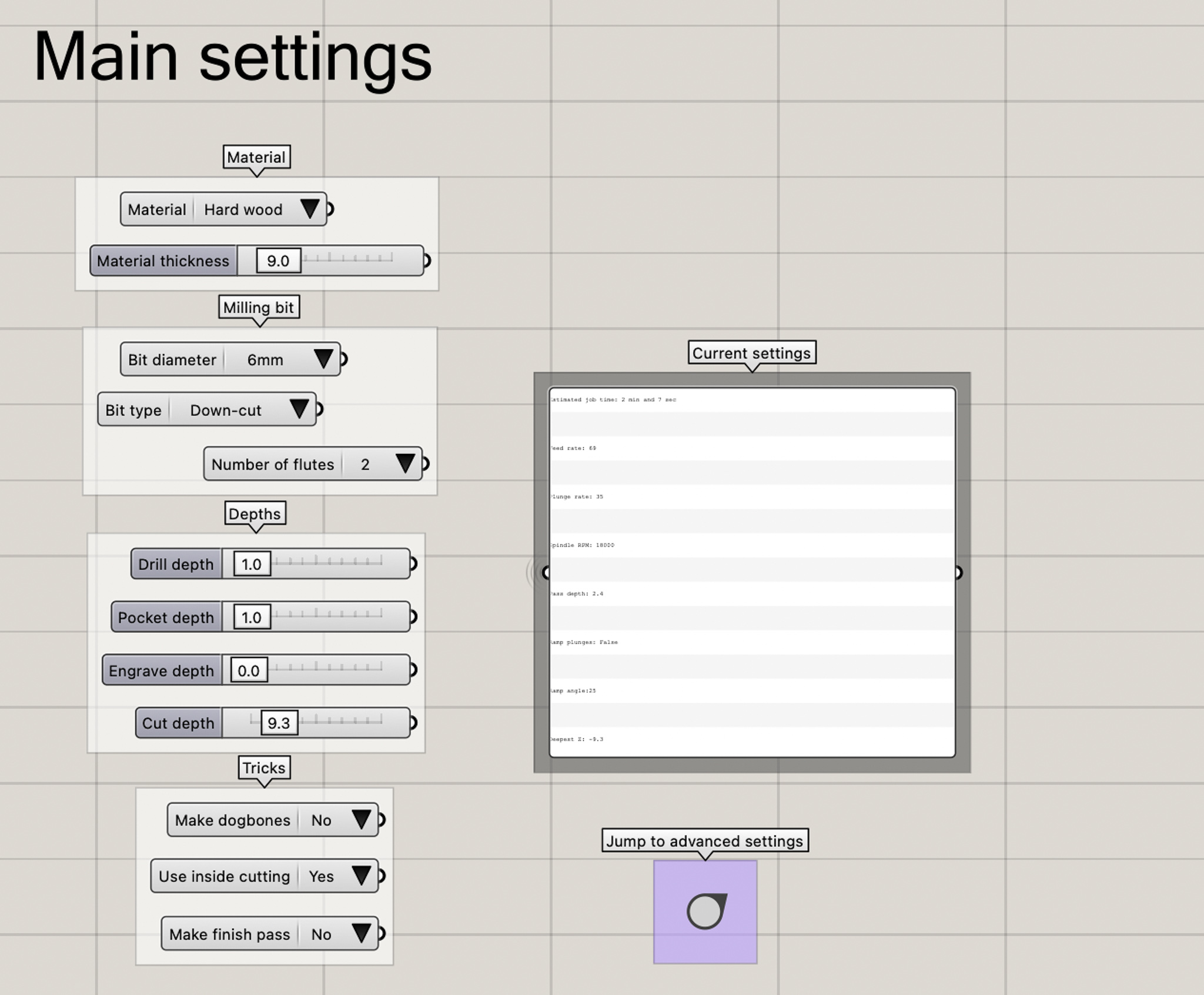

Machining settings in Grasshopper

- Type

grasshopperin command line > Grasshopper window opens > Click on green tile (top left one) - Adjust

Main settings- For multiplex:

Material: Hard wood Use inside cutting: yes> cut inside design lineUse inside cutting: no> cut outside design line

- For multiplex:

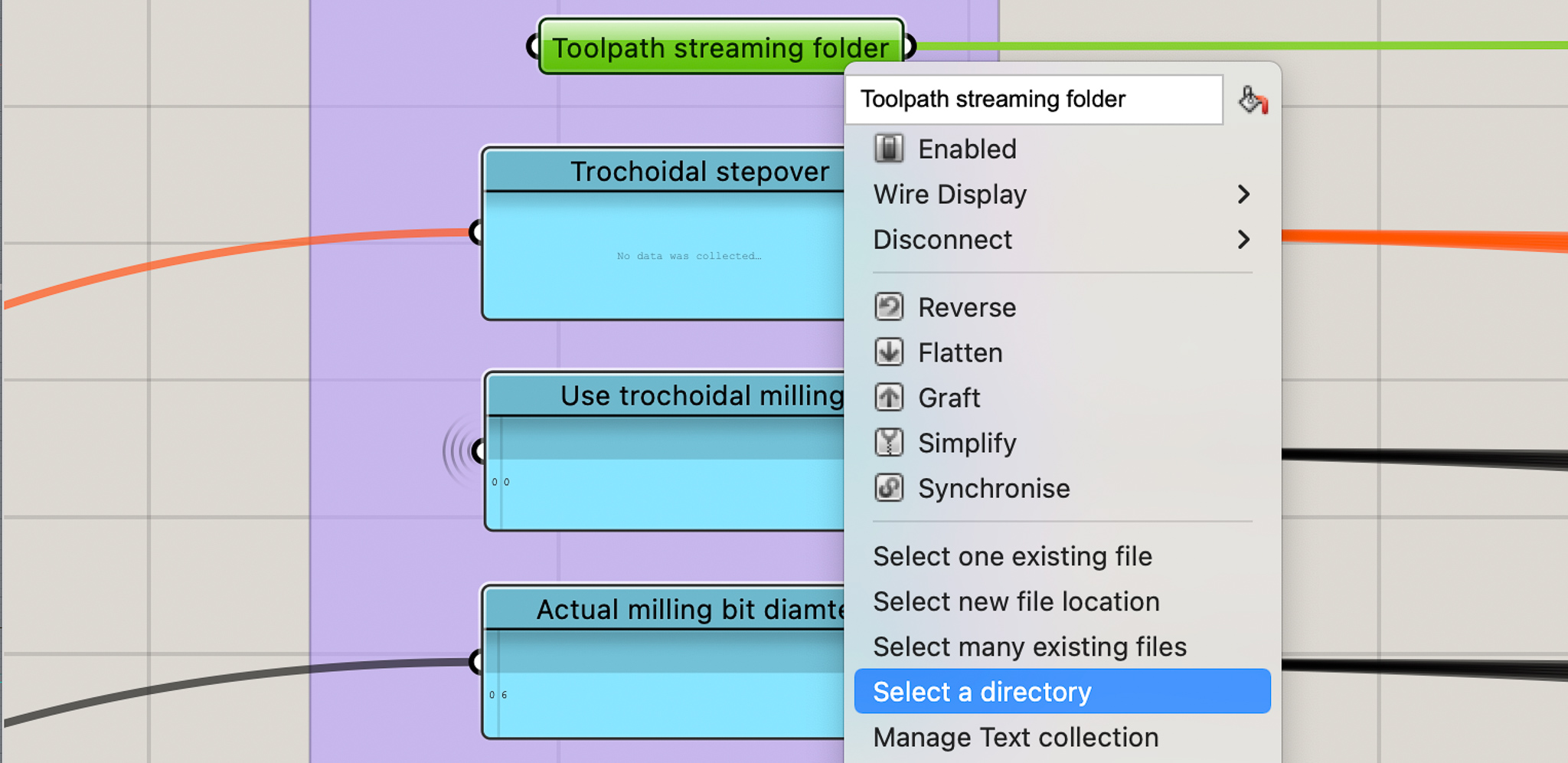

When using the templates the first time, configure where the generated toolpaths are saved

Screw markers toolpath

- Create circles with tool diameter & copy to screw positions

- Set drill depth to

1mmin grasshopper - Select all screw circles

- Right click

CNC drill>Change object layer - Copy

\1 Drill - Bark beetle.NCfile from cnc_jobs folder

Other toolpaths

- Create next toolpath (from inside out) e.g. engrave

- Right click

CNC engrave>Change object layer - Copy engrave file from cnc_jobs folder

Sacrificial layer surfacing

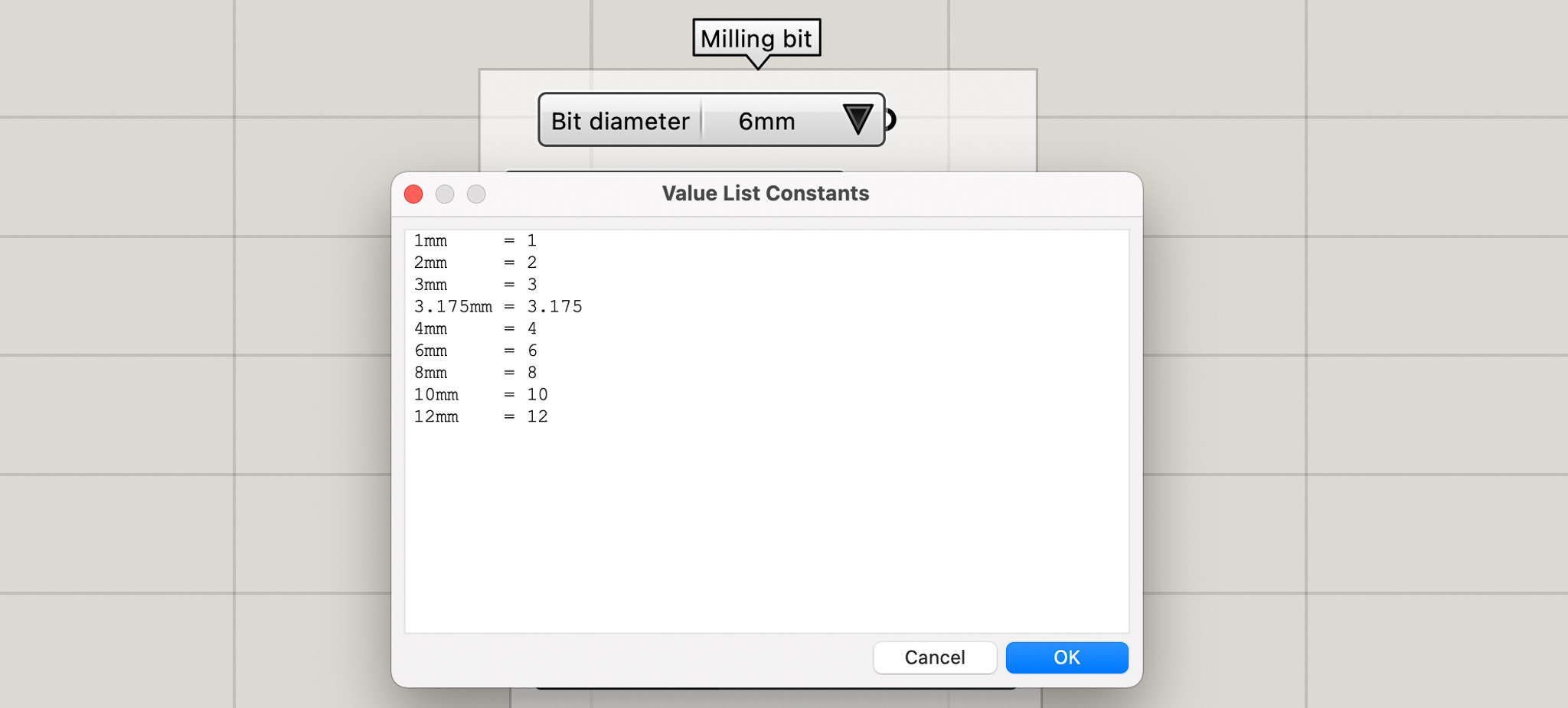

To level the sacrificial layer we use a 20 mm tool. By default grasshopper doesn’t have a 20 mm tool in the Bit diameter dropdown. It’s easy to add one with a right click on bit diameter > Edit and then just adding the custom tool to the list

This is some ready GCODE for surfacing with a 20 mm tool. It covers an area of 1230 x 2450 mm. That’s bigger than the MDF plate because it goes 5mm over the edge of the plate all around.