Fusion 360 CAM

This page shows the basics of creating 2D pocket and contour toolpaths.

Setup

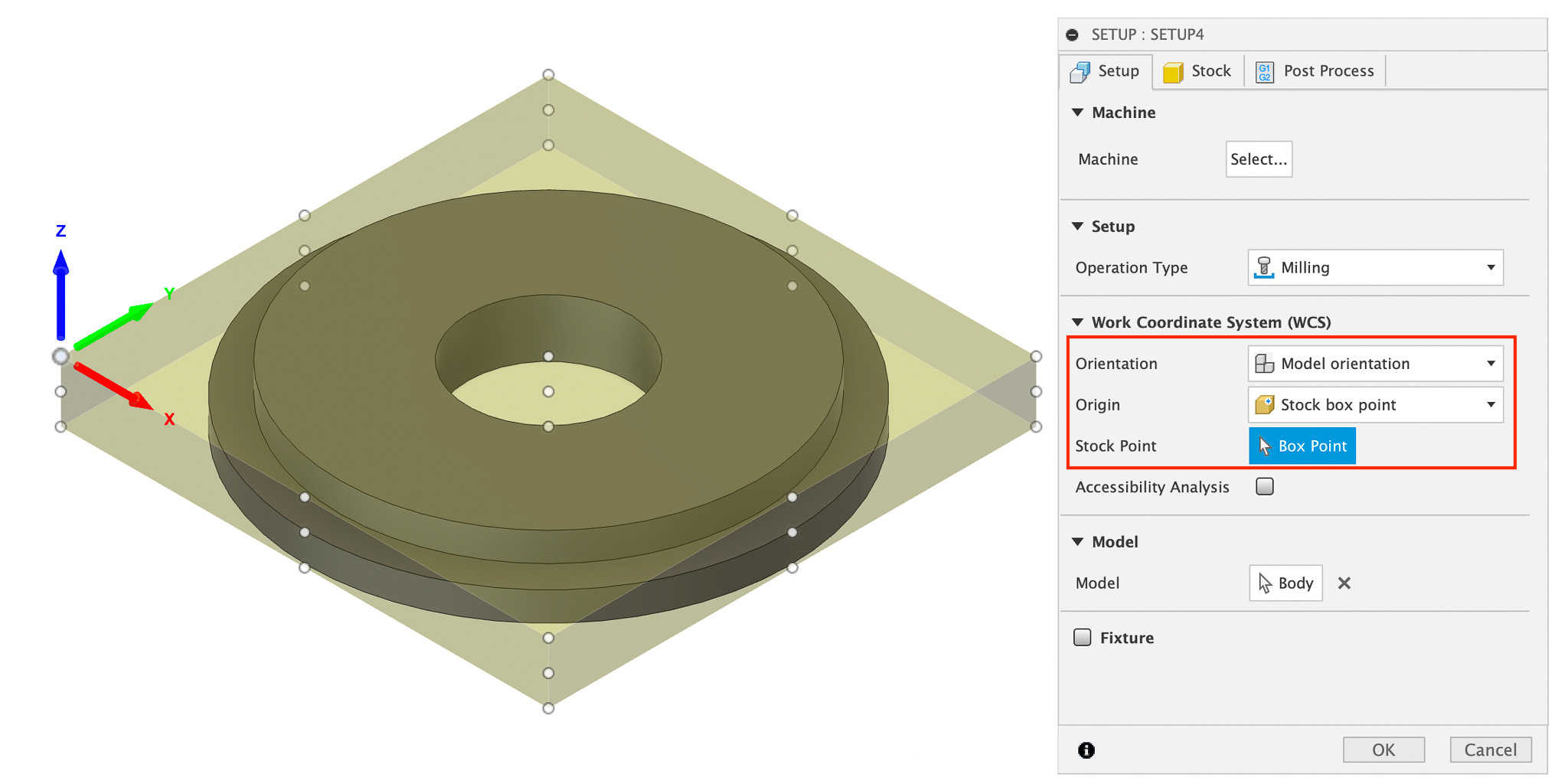

In the setup we define the stock (raw material) dimensions and where the origin is

Setup > New

We want the origin to be in the bottom left corner. X,Y and Z should point in the directions as shown in the picture

We want the origin to be in the bottom left corner. X,Y and Z should point in the directions as shown in the picture

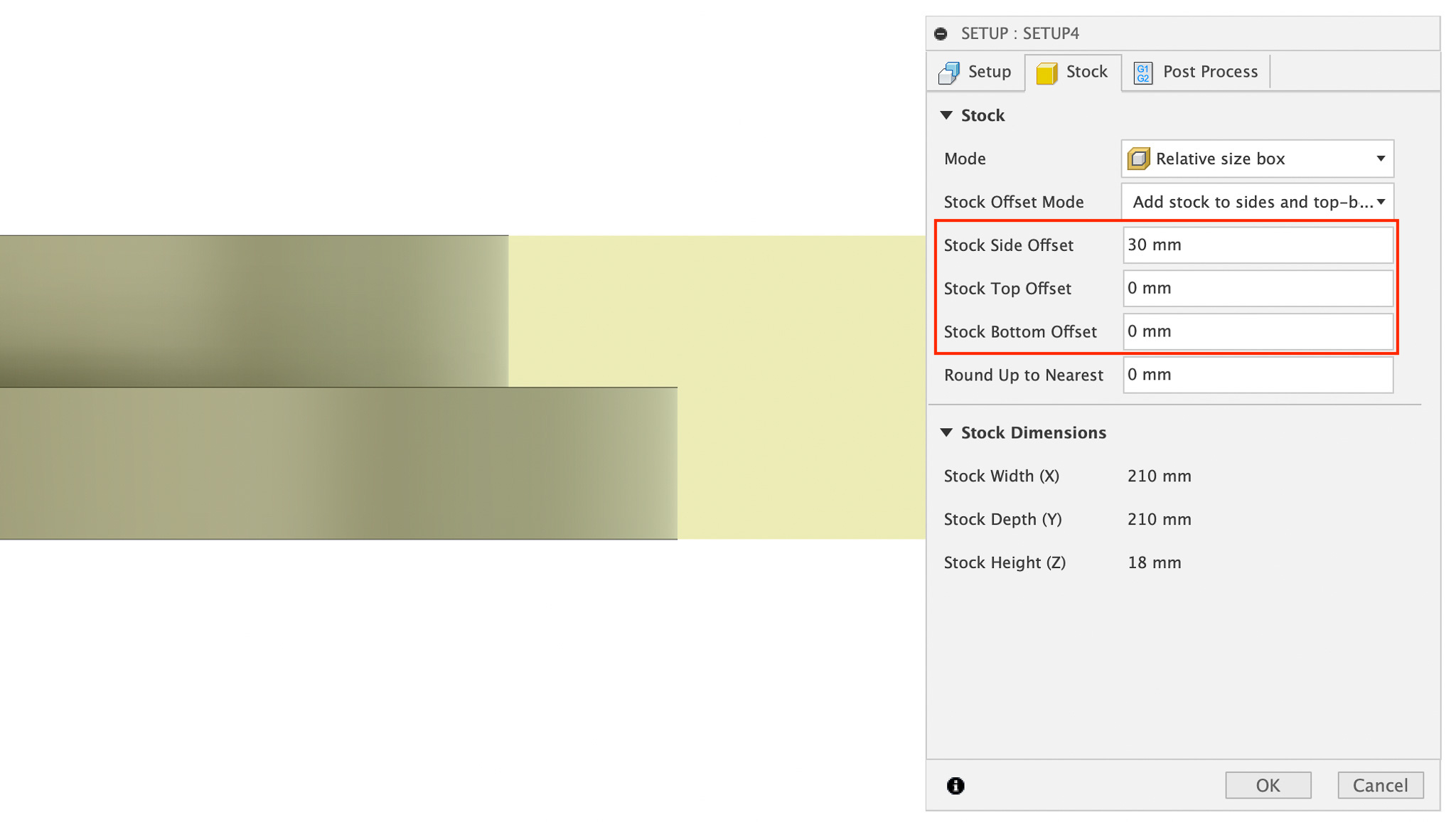

In general we don’t want any stock material above and below our model (

In general we don’t want any stock material above and below our model (Stock Top Offset = 0 and Stock Bottom Offset = 0)

I use Stock Side Offset = 30 to have space around the model to screw the stock to the sacrificial layer

Create tool

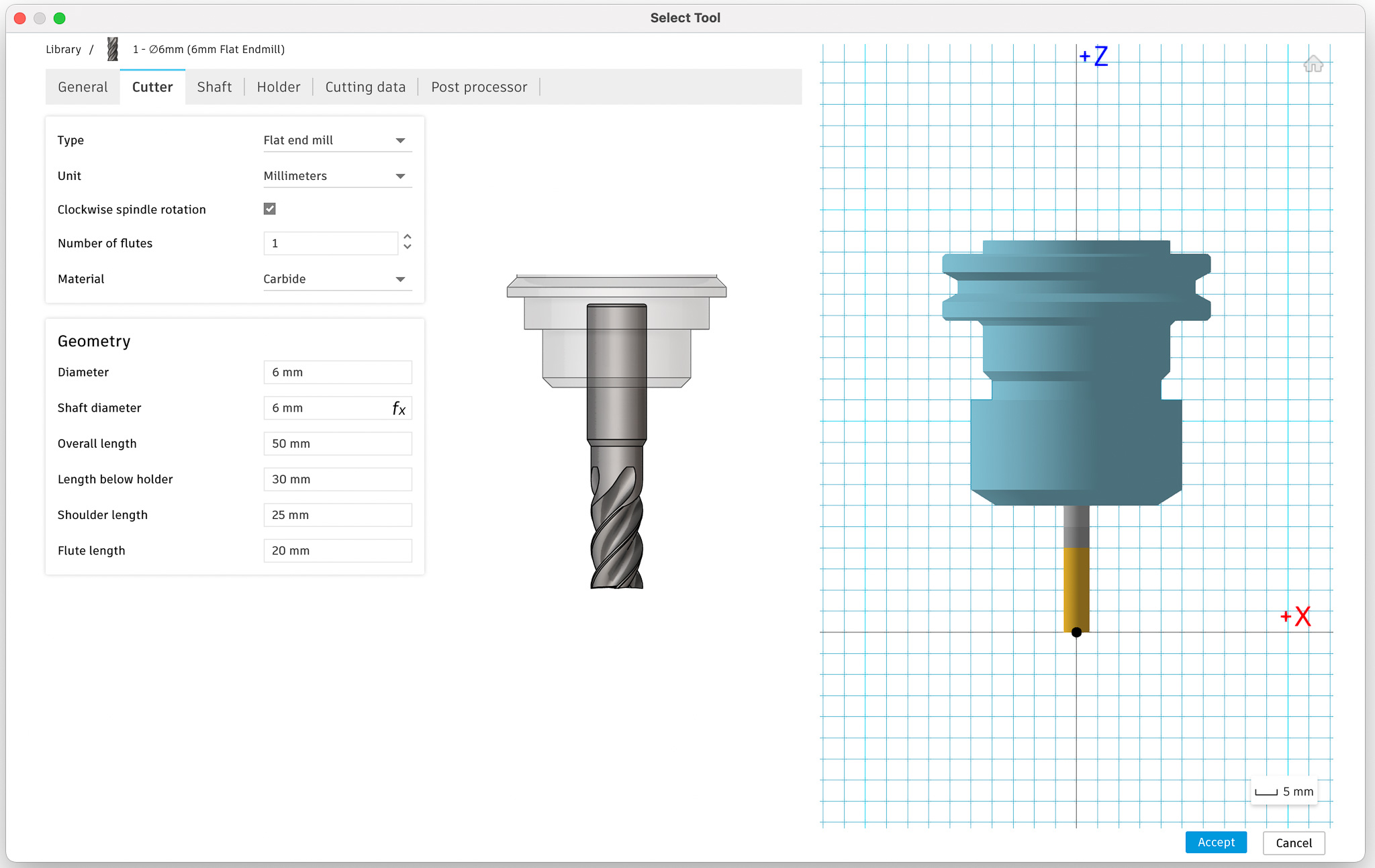

Next we’re going to create the tool that is going to be used to mill our model

Manage > Tool Library

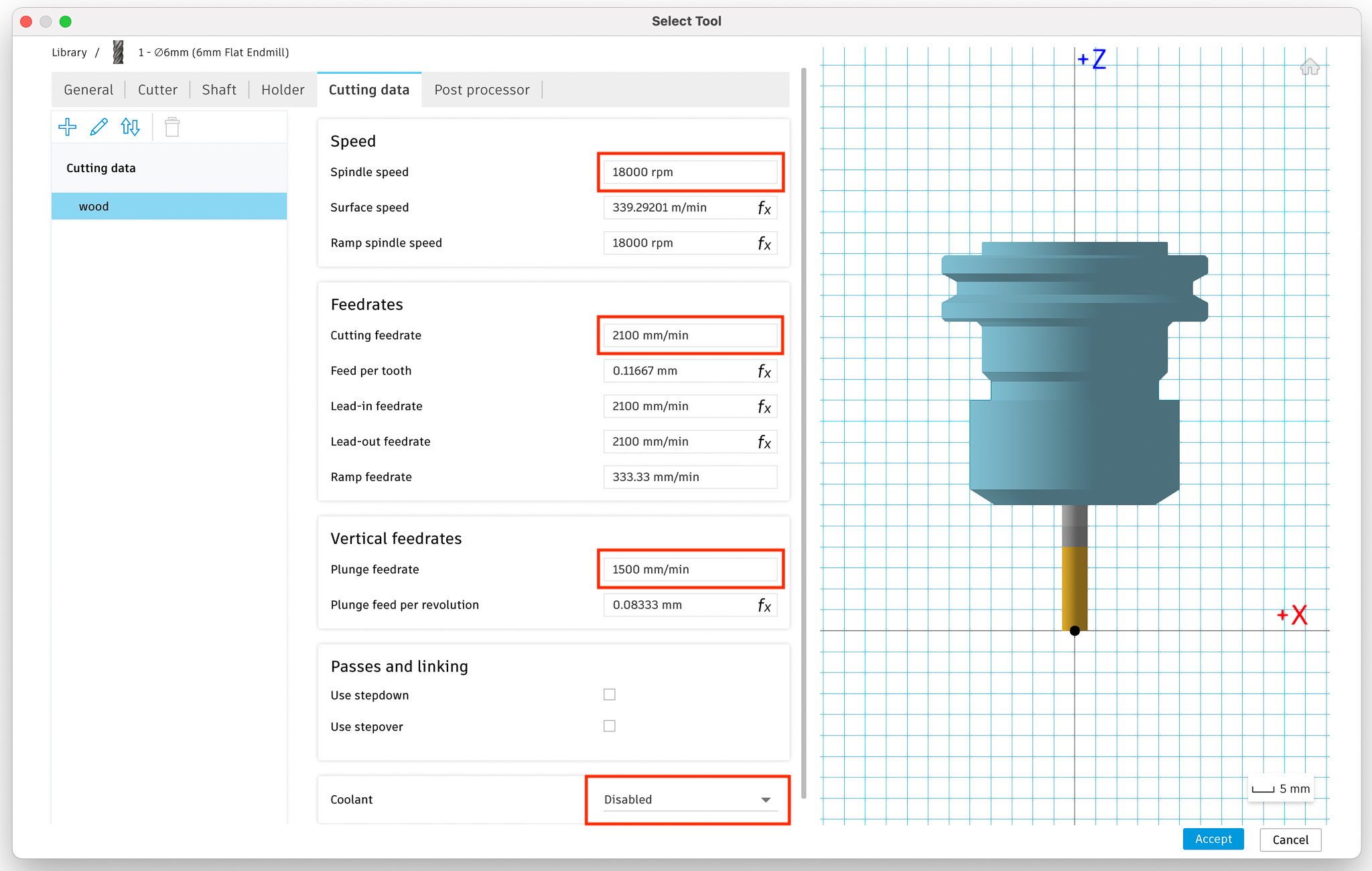

The Cutting feedrate and Plunge feedrate shown here match the one used by Grasshopper when selecting hard wood

2D Pocket toolpath

I use this toolpath to cut a pocket

2D > 2D pocket

Tab: Tool

Select the tool that we created earlier. All the values will be filled in based on the tool settings

Tab: Geometry

Select the part of your model where the pockets should be cut

Tab: Heights

No change needed

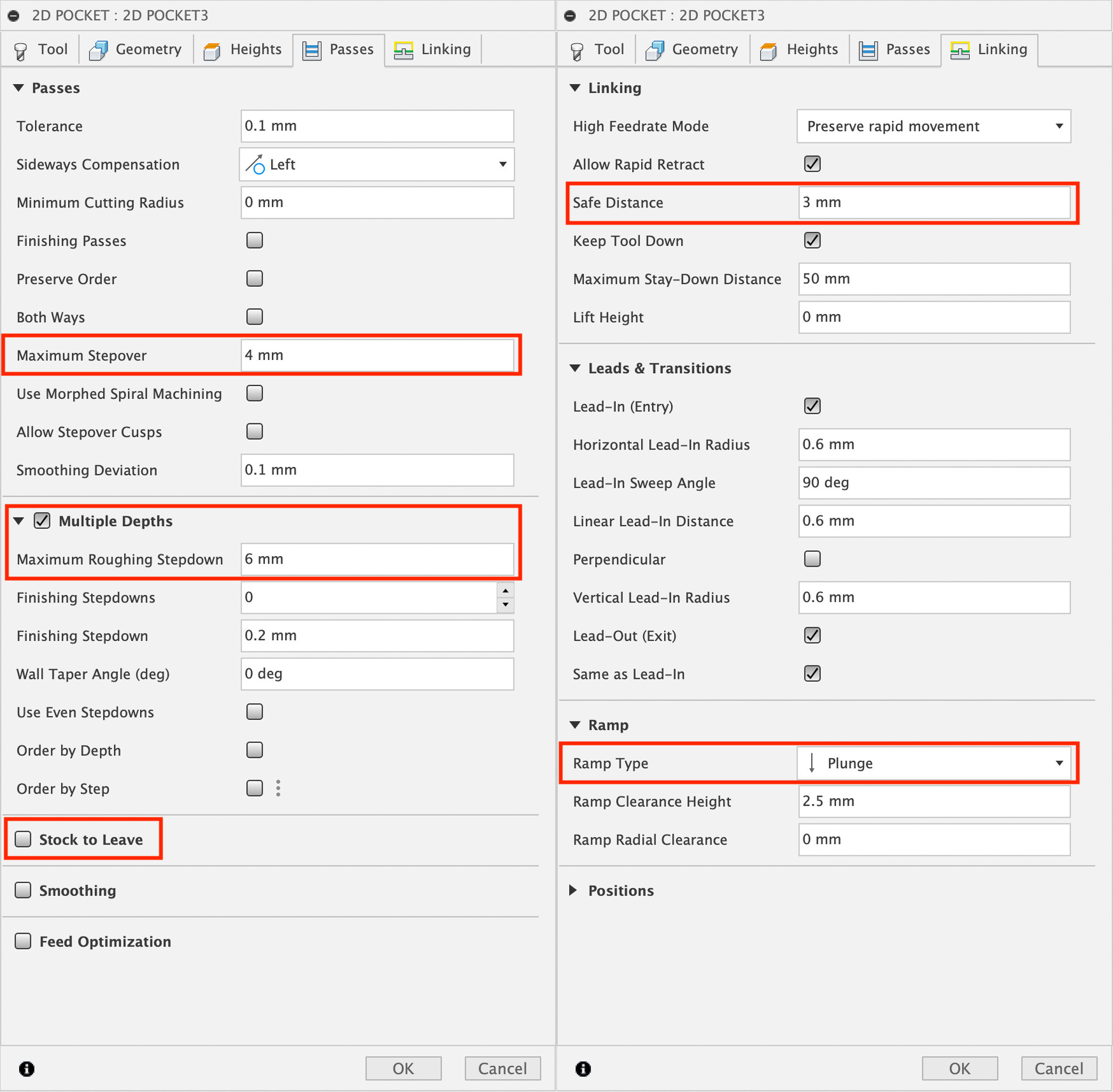

Tab: Passes

Set the Maximum stepover: 75% of the tool diameter is a good starting point. This defines the horizontal distance between passes.

Use Multiple Depths to go to the final pocket depth in multiple steps: 6 mm stepdown is a good starting point

Uncheck Stock to Leave

Tab: Linking

Set Safe Distance = 3 mm

When machining wood, Ramp Type = Plunge can used to speed up things

2D Contour toolpath

I use this toolpath to cut the contour of my model

2D > 2D contour

Tab: Tool

Select the tool that we created earlier. All the values will be filled in based on the tool settings

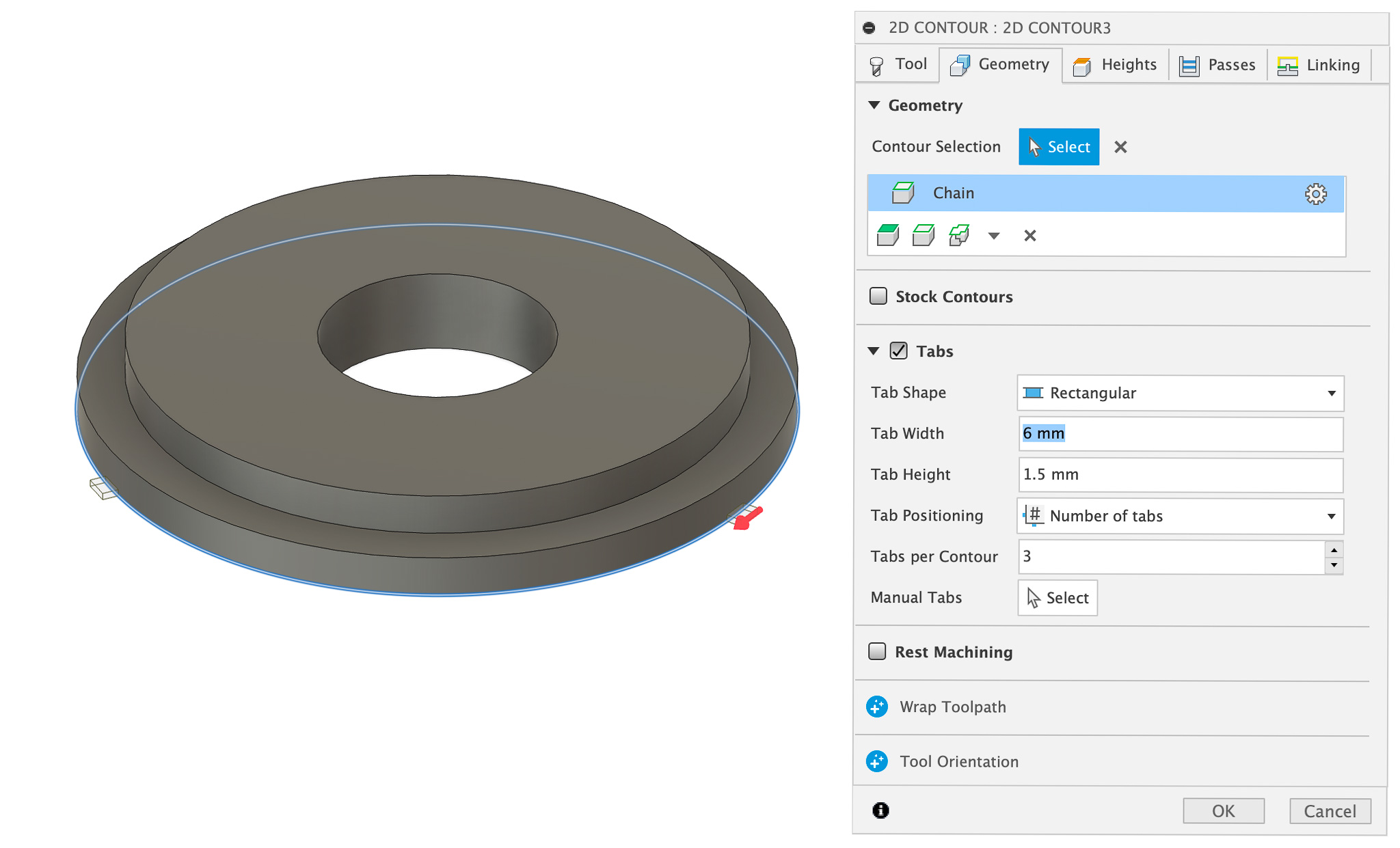

Tab: Geometry

Select the contour that should be cut out Configure Tabs if needed

Tab: Heights

No change needed

Tab: Passes

Use Multiple Depths to go to the final cut depth in multiple steps: 6 mm stepdown is a good starting point

Tab: Linking

Set Safe Distance = 3 mm

Simulate

Once the toolpaths are complete it’s a good idea to simulate them to check that everything looks good.

Actions > Simulate

NC program

Post processor

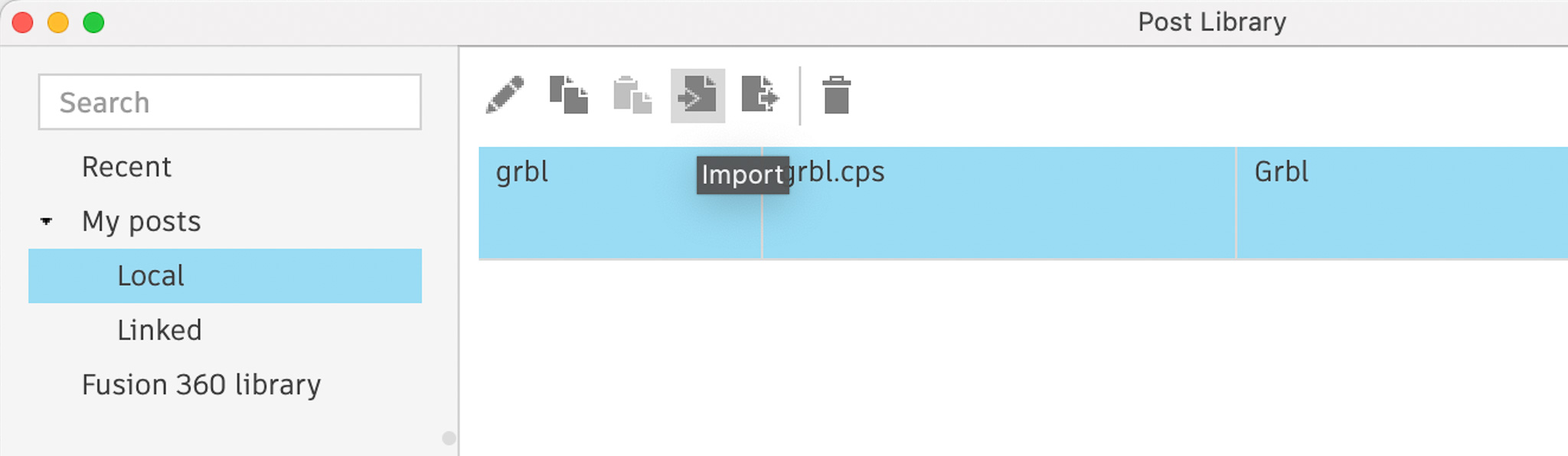

Download GRBL post processor

Manage > Post Library

Select Local, click import icon and then select the downloaded file

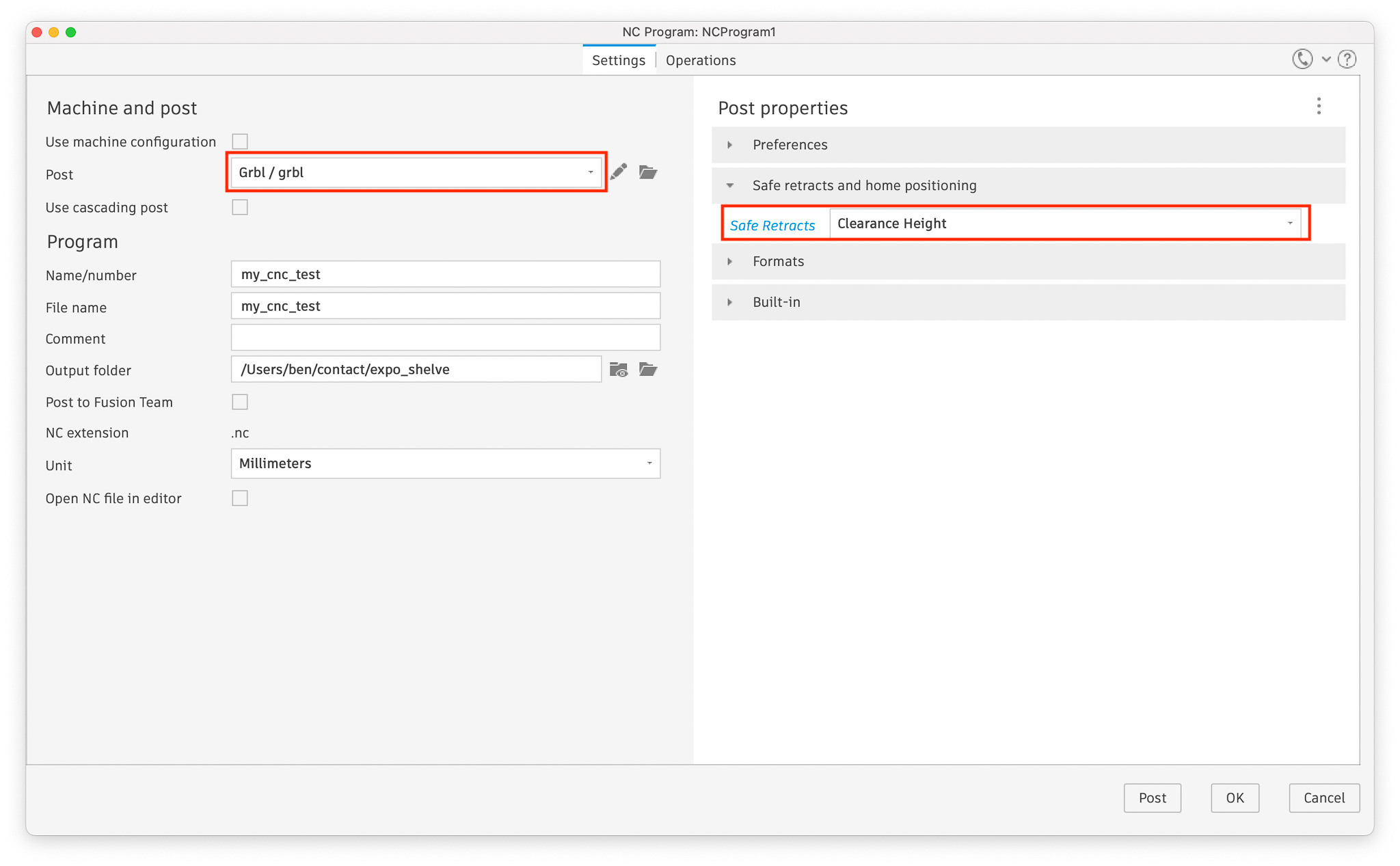

Create NC program

Right click on Setup > Create NC program

Select the GRBL post processor downloaded earlier and adjust the Safe retracts setting

If Safe retracts setting is not adjusted to Clearance Height the program will make fast moves with the tool in the material. This will ruin the piece, break the tool and potentially damage the machine

The created .NC file can be copied to the machine and executed

Resources

This video is a good introduction to designing and machining simple furniture with fusion 360

The Trace and Engrave toolpaths are suitable for engraving. This video explains the differences between the two.